Features

|

・The very best Oldham's coupling (large size). ・Features a high-speed rotation greese resupply mechanism. |

|

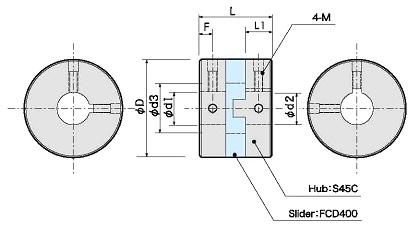

Configuration and materials

|

|

・Key groove shape complies with new JIS standards. |

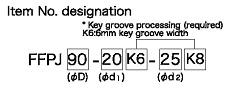

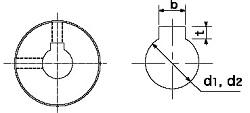

Dimensions of key groove shape |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dimensions

| Item No. | D |

Standard hole diameters ød1,ød2 H8 | d3 | L | L1 | F |

State with no fitting section gap grease (μ) |

M | Fastening torque* (N⋅m) | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FFPJ90 | 89.5 | 20 | 25 | 30 | 35 | 40 | 45 | 46 | 66 | 24 | 12 | 15-20 | 8 | 16 | ||||||||||||||||||

| FFPJ110 | 109 | 25 | 30 | 35 | 40 | 45 | 55 | 56 | 80 | 29 | 14.5 | 17-22 | 10 | 33 | ||||||||||||||||||

| FFPJ130 | 129 | 30 | 35 | 40 | 45 | 55 | 65 | 66 | 94 | 34 | 17 | 19-24 | 10 | 33 | ||||||||||||||||||

| FFPJ150 | 149 | 35 | 40 | 45 | 55 | 65 | 75 | 76 | 110 | 40 | 20 | 21-26 | 12 | 50 | ||||||||||||||||||

|

FFPJ180 |

179 | 40 | 45 | 55 | 65 | 75 | 85 | 86 | 130 | 48 | 24 | 25-30 | 12 | 50 | ||||||||||||||||||

* FFPJ couplings require key groove processing.

* Always indicated the hole diameter and key groove dimensions.

Specifications

|

Item No. |

Rated torque (N⋅m) |

Maximum Rotating speed (rpm) |

Allowable parallel misalignment (mm) |

Allowable angular misalignment (°) |

Allowable end play (mm) | Torsional rigidity (N⋅m/rad) | Moment of inertia (kg⋅m2) | Mass |

|---|---|---|---|---|---|---|---|---|

| (Kg) | ||||||||

| FFPJ90 | 160 | 10,000 | 1 | 0.2 | 0.4 | 3x105 | 3.3x10-3 | 3 |

| FFPJ110 | 200 | 10,000 | 1.1 | 0.2 | 1.45 | 4.5x105 | 9x10-3 | 5.3 |

| FFPJ130 | 260 | 10,000 | 1.3 | 0.2 | 0.5 | 6.5x105 | 2x10-2 | 8.7 |

| FFPJ150 | 320 | 10,000 | 1.5 | 0.2 | 0.6 | 8x105 | 4x10-2 | 13.3 |

| FFPJ180 | 400 | 10,000 | 1.8 |

0.2 |

0.8 | 1x106 | 0.1 | 23 |

1. Due to grease limitations, standard thermal resistance is 150℃ or below.

2. This coupling is a high-precision, high-rigidity coupling, so the parallelism of the shaft is especially important. If there is declination then every 90° there will be rotation resistance,

producing rotational vibration and noise.

3. The amount if eccentricity must also be kept at a minimum for high-speed rotation.